Constructive Details

Our equipment, manufactured to order, is built in an artisanal way, that gives us the possibility of giving it a personalized finish according to the client´s taste and preference.

Panels and Boxes

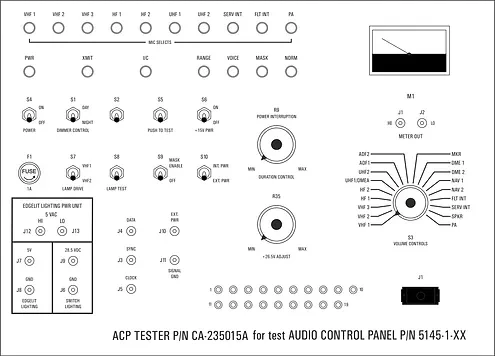

By default, the Equipment is built in vertical panels, with a standard measure of 19 inches wide with height according to the requirements, in multiples of 1 3/4 inches.

Attached to the panel is a tray for mounting internal components, such as power supply, transformer, printed circuit. For protection of internal components and adhered to the front panel, a protective cover 12 inches deep and high according to the size of the panel is placed. To allow rack mounting, the panels have perforations in standard sizes. If the design and the characteristics of the Equipment allow it, the customer can choose to request that the Test Set be built on a panel that, by means of horizontal mounting, is placed in a suitable measurement box

Panel Registration

Superimposed on the aluminum panel, a bilayer material plate, Gravoply brand, registered trademark of Gravograph or Laserables Series of Innovative Plastics Inc. is placed. The customer has the option of choosing the color of the bilayer material. In the same one, by means of Laser, the inscriptions of the panel are recorded

Components

The components of the Test Equipment are of recognized brands and aeronautical quality

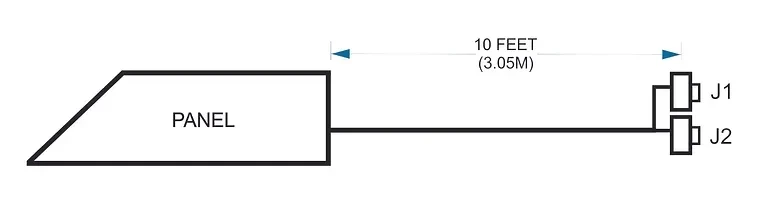

Cables

Cables constructed under M16878 and M22500 standards are used. All equipment cables, without exception, are numbered and a list of connections based on the cable numbering is included in the Equipment Maintenance Manual.

Printed Circuits

The printed circuit boards we design are built by world-renowned manufacturers.

Logos

To strengthen the personal touch of the Equipment according to the preferences of the client, he can choose to request the recording of his logo on the bilayer material of the front panel.

.webp)